Monday, September 13, 2021

Passing Time at the Airport

Sunday, September 12, 2021

In the air again

A quick trip to the Pacific North West.

As we start our descent into Sea-Tac, the sun and clouds frame our shadow with a circular rainbow.

I don't think I've flown the approach from the North into Sea-Tac yet. Great scenic loop over the Pudget Sound and past downtown Seattle. However, I don't think the locals are as excited about this flight route as me ...

Tuesday, September 07, 2021

Der Tunnel - Verbindungsbahn der S-Bahn Stuttgart

Monday, September 06, 2021

ETE: Bay Area Module Group at Oakland Aviation Museum

601 004 traveling across the Danish country side.

Fast-forward 50 years: 442 206 crosses a bridge that could be located in the Black Forest.

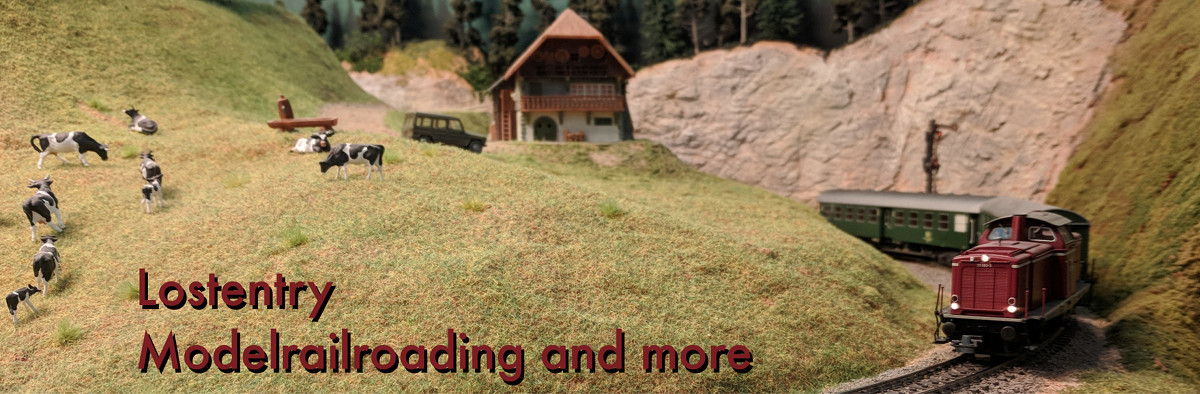

Today I hung out with the ETE Bay Area Module Group at the Oakland Aviation Museum. I even brought some trains with me.

This was a great opportunity to run the BR 601 in Intercity service in its full length consist with 8 cars, which looked great running on the long main line loop the group has set up.

I had a lot of fun running trains, chatting with friends, and enjoying the atmosphere. The museum was quite empty, which was a pity since there's lots to see besides model trains, especially if you're into planes.

Saturday, September 04, 2021

Roco 43012 - Preparing for an Outing

I haven't worked on the BR 601 3-rail conversion project for almost 3 years now. I was stuck on a mechanical drive train problem, how to install lights, and how to power the sound decoder for the rear motor unit. In addition, the full train is too long for the Welztalbahn. So several intermediate cars stayed in the box, and a shortend train with the two power cars sat on a storage track in staging.

Now I have an opportunity to run the train in its full-length glory on a larger layout in public, so I finished swapping all wheel sets for their respective AC counter parts and installed the hand rails at all doors. I'm not going to be able to finish installing the sound decoder in the second motor unit before Monday, nor lights or passengers. That will have to wait for another time. I hope that I can resolve the drive train problem today or tomorrow.

Friday, August 27, 2021

SVL: August Modern Ops Session

For the first time in months, I was able to participate in an ops session at Silicon Valley Lines in person again. This was a nice opportunity to catch up with other club members and enjoy the atmosphere of being in the layout room. I ran Bayshore Yard, which was a very relaxed assignment with plenty of opportunities to railfan trains run by remote operators.

Sunday, August 22, 2021

1000 pieces in 10 days

Sunday, August 15, 2021

Delivery from Germany

I have not been to Germany for a while, so various ebay orders have been piling up at my parent's place. This summer two of our children went to visit family, and they brought back a treasure trove of stuff. Lots of original paperwork from the 1970's, including schedule books, maps, and a Güterkursbuch from 1972. Various books and magazines about the Bundesbahn in the 70's, some original artifacts, and some history books about railroads in Württemberg. I also picked up a collection of original rules and regulations from the 1930's, 40's, and 50's.

Lots of stuff to go through. I'm planning to post some of the more interesting original paperwork here over time.

Friday, August 06, 2021

Untergroeningen Station Building (2)

[ part 1 ]

I've constructed the station building shown in part 1 in Tinkercad, which is a very easy to use online 3D CAD tool. I know it mostly as a tool for users that want to send the resulting model to a 3D printer. Tinkercad makes exact sizing of the model very easy. Measurements of elements are readily accessible, and changing values is trivial.

Developing a 3D model from photos and drawings is interesting. Especially the roof geometry remained a challenge, though at last I finally figured out what the geometry actually must have looked like, based on how the roof lines develop from the walls and what I can deduce from photos taken at eye level from the ground.

I didn't want to 3D-print the station building, but rather wanted to build a paper model. Much more economical than springing for a 3D-printer and filament. There are many instructions and tools to unwrap 3D models. Dedicated payware like Pepakura (Windows only), Unwrap3D, plugins to Blender, or the native UV Editor built into Blender. I found that unwrapping the whole building became very cumbersome, so I exported only the roof structure as STL from Tinkercad, imported that to Blender, manually set seams using the UV Editor, and constructed a sensible unwrapped roof. Exporting the unwrapped roof from the 2D view in Blender leads to a very low-resolution PNG. I took a screenshoot instead, scaled it to the right dimensions in GIMP, and printed it. Not high-quality, but more than sufficient to cut the shapes. Since the walls are basic boxes I just measured and cut lengths of card stock in the right dimensions.

The photo above shows my first attempt of the paper building on the Untergroeningen module. While the walls look properly proportioned in the 3D model on screen, the paper model is a bit too plump, or fat, when comparing to prototype photos. The roof seems to be a bit too flat as well. The next version is going to have slightly higher walls, and a slightly steeper roof. Adding 3mm to each story and the roof should do the trick.

When comparing with a freight car on the tracks, the building sits too low as well. I need to raise the ground a few millimeters and have a proper building foundation.

Otherwise, I'm pleased with how this scene is developing.

Tuesday, August 03, 2021

Untergroeningen Outbuilding - Completed

Thursday, July 29, 2021

Untergroeningen Station Building

With the outbuilding mostly completed, I'm starting to work on the station building of Untergroeningen. I have photos. I have an aerial photo. What I don't have are reliable measurements. I made drawings and a mockup from paper, but I felt that the building proportions were not quite right. A couple days ago, I started constructing the building in 3D from the drawings I made earlier. The idea is to replicate viewing angles I have as a photo and see what the 3D model would look like. This is not perfect, since lens distortion and other optical effects get in the way, but I'm hoping to get closer. Here's me first try. Not too shabby, but the proportions are indeed not quite right. I think I might have made the building a bit too deep, but it's hard to tell on the screen.

If only I could make a paper model from the STL 3D model ...

Sunday, July 25, 2021

Untergroeningen Outbuilding (10)

We're coming close to the end of this build. The Outbuilding is basically done. It's missing only the windows and the foundation. The windows will come when I have decided whether to scratch-build, kitbash, or 3D-print them. The foundation will be part of the final installation in the Untergroeningen module, so will come at a later time.

Meanwhile, I have completed the garage doors, added the gable barge boards, a venting pipe, downspouts, and the concrete "Schamwand" in front of the restroom doors. That wall likely used to be made from wood way back when the restrooms were built, and replaced with a concrete wall as the old wooden wall was falling apart. I assume the building got a refresh in the early seventies. Hence, the relatively new roof and mostly spotless garage door, too.

None of the prototype photos I have show the outbuilding in the early seventies, so I took some artistic license here.

[ finale ]

Sunday, July 18, 2021

Untergroeningen Outbuilding (9)

[ part 10 ]

Friday, July 16, 2021

Untergroeningen Outbuilding (8)