Saturday, October 31, 2015

BRAWA 0458: Upgrade with ESU Lokpilot 4.0 micro and ESU Powerpak

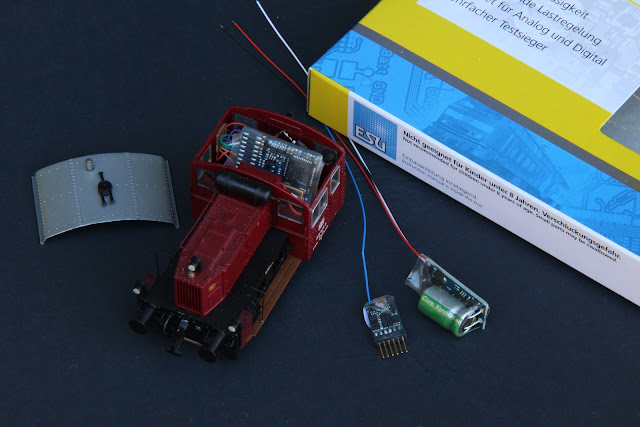

I converted this BRAWA Koef II to digital operation using a regular Lokpilot 3.0, which just barely fit into the cab. Switching cars with this little locomotive is a lot of fun, so I sprung for a Lokpilot 4.0 micro DCC and the ESU Powerpak.

Here's a view of the locomotive with the cab roof off. It's easy to see how much smaller the new decoder is...

The first step was to connect the Powerpak to the respective soldering pads on the decoder. The pads are just as small as one would expect from such a tiny decoder.

Technically, the fine tip of my soldering iron is still too big for this job but I managed to solder the cables in place with the edge of the tip. Using a magnifying glass, reading glasses, steady hands, and going slow helped with this step.

The motor and pickup wiring inside the locomotive is hooked to a 4-pin connector. I unsoldered the existing decoder, soldered connections for the new decoder (I should have ordered the version with wires attached... ), and after some time --- interrupted by tonight's Halloween activities --- I'm testing the decoder on the layout.

Out of the box, with no tuning in the decoder settings whatsoever, the Powerpak already improves performance on the not so commonly used track in the industrial area. In speed step 2 the loco smoothly rolls over turnouts where it used to stop when going that slow. The only indication that the Powerpak is doing its job is a slightly jerky motion on dirty track. I should be able to tune that in the decoder settings.

Time to dress the cables a bit more, program the decoder, get a "Rangierfuehrer" in the cab of the Koef, and put the cab roof back on.

[Previous installments of the Koef II conversion: Part 1, Part 2, Part 3, Part 4 ]

Friday, October 30, 2015

Silicon Valley Lines: Nowheres Yard

During tonight's operation session, Gabe is taking train #370, made up of mostly white MDT reefers, northbound to the Tracy creamery and Victoria. Meanwhile Josh in the foreground gets rock train #420 ready to depart for the quarry interchange in Jacksonville.

The transitional yard tracks in the foreground are quite busy with cars having arrived on earlier trains and cars ready to leave with trains later in the session. My instant switch list creator software had quite a workout tonight getting the Nowheres hump yard organized (not pictured).

Thursday, October 29, 2015

Ground

In the last couple days I fixed the track in place, installed cork underlay under and around the locomotive shed and the adjacent parking lot, and glued the track in place. It actually sits on a bead of clear silicone, but close enough. Tonight I got the gardens tacked in place and shaped the ground in the area using tinted Scuptamold and the artists spatulas in the front of the picture.

When I was done, I realized I hadn't painted the track yet. That's gonna be fun in tight quarters ...

Monday, October 26, 2015

Saturday, October 24, 2015

Talheim Locomotive Shed

The Koef II in Talheim needs a home. Now that the Schrebergarten is ready for installation on the layout, and the run-around track is rearranged, it's time to build the locomotive shed. I used Vollmer's Nr. 5750 "single stall engine shed" kit as the basis for this kit bash.

I assume there is some history to the building and it used to house a small steam powered switcher, that has been replaced with a Koef a while ago. The building thus is in a somewhat dilapidated but still serviceable condition. The spur to the shed comes off the curved industrial track to Kopper and Gregorius, and hits the room wall at an angle. I wanted to have as much shed as possible, and built the shed as a 3/4 relief with the rear cut off. I also didn't want to build yet another red brick structure on the layout, as they are not really typical for the southern Black Forest, and the colors also needed help to differentiate the building some more.

This required a few modifications to the walls and roof. I really liked the sky light, so I took the liberty of turning the roof around and move the chimney just before the cut in the rear of the shed.

Thankfully, this Vollmer kit is flexible enough to allow hiding most of the cuts. At the end of the first evening I tested the modified building at its destination on the layout, and was quite satisfied with the result.

I spray-painted the brick a sandy earth color, turned the green windows into a middle-grey, and painted the green doors brown with faded green paint using several washes of shades of brown. Roof and walls were dirtied up and weathered heavily using acrylics, washes, and pigment powders.

I can almost smell the mold in the walls ...

With the rear cut off, the shed has just enough space to house the Koef II or the Koef III that are usually assigned to Talheim.

Now that the shed dimensions are fixed and I have a better feel for the area, I can move on to finishing the area around the garden spots right behind the shed, install a few more trees and bushes, and then come back build the floor and servicing area around the shed.

Sunday, October 18, 2015

Yosemite Mountain Sugar Pine Railroad

On a rainy Sunday morning I found myself today in the Sierra Nevada foothills waiting to "Ride the Logger".

This was a fun one hour trip on an old logging right of way, with 3 truck Shay Nr. 10 leading the train. We very much enjoyed the -- almost private -- early morning run through light drizzle into the forest.

Apparently a tour bus was booked for this departure, but they didn't show. So this trip had a total of six passengers...

Tuesday, October 13, 2015

Kit-bashing a Vollmer locomotive shed

This locomotive shed needs to go into a rather tight spot against the wall in Talheim, so it needs a few modifications. Franziskaner helps to keep all the cuts nice and straight ...

Sunday, October 11, 2015

Schrebergarten - On the layout

Test fitting the garden spots on the layout. Despite the runaround modifications in Talheim, the gardens still fit the space quite nicely. Some slight adjustments and gentle application of Scuptamold, paint, and ground cover will blend everything together. With that done I can also finish blending layout and backdrop in this area.

Earlier posts describing the build can be found here.

Schrebergarten - Second garden

While finishing the first garden in June, I had run out of fences and didn't really want to fill the garden area before it could be properly delineated. Vacation, events, other projects, work, and summer in general got in the way, so I didn't return to working on the gardens until last weekend.

I painted and weathered enough fences to close the gap, and then started with the remaining vegetables from Busch's kit 1222, and some more Noch plants made from various fibers and foliage.

Contrary to the first garden, the second one was supposed to be well maintained and very neat.

Making and planting the vegetables takes forever, but isn't particularly hard. Once I was satisfied with the vegetable part of the garden, I enclosed the remainder with blue painters tape and made a nice dense lawn from Scenic Express' Late Summer static grass.

Saturday, October 10, 2015

Patio Roof Replaced

The patio roof is leaking. With all the rain in the forecast this winter, it was time to do something about that. Last weekend I picked up (almost) enough material to redo the roof. This is the second time I'm doing it. The previous time was soon after we moved into this place. However, 2 years later a several rafters in the wood framing over the patio needed replacement. The contractor building the new framing also reinstalled the roof. Let's just say they didn't do a stellar job putting the roof panels back together...

This morning Pascal and I got to work on taking off the old panels, and install new ones. We worked our way from left to right. By noon a few new panels are installed. I'm intentionally not taking off the old panels all at once to reduce wobble when walking on the patio roof framing.

The little cat is keeping me company throughout the day.

The lawn is collecting panels. Old ones on the left, new ones on the right.

At the end of the day I'm installing the last panel, and finished just in time before it got too dark to work outside on the roof safely.

Of course I did have to make a run to Lowe's in the middle of the afternoon, since I was one panel and a few closure strips short...

This morning Pascal and I got to work on taking off the old panels, and install new ones. We worked our way from left to right. By noon a few new panels are installed. I'm intentionally not taking off the old panels all at once to reduce wobble when walking on the patio roof framing.

The little cat is keeping me company throughout the day.

The lawn is collecting panels. Old ones on the left, new ones on the right.

At the end of the day I'm installing the last panel, and finished just in time before it got too dark to work outside on the roof safely.

Of course I did have to make a run to Lowe's in the middle of the afternoon, since I was one panel and a few closure strips short...

Friday, October 09, 2015

The Magic Flute

Musicians from the SF Opera visited the office today, and played the Overture of The Magic Flute with musically inclined co-workers on-stage. They went on to tweak the arrangement a bit, discussed how the orchestra comes together in rehearsals, talked about the role of conductor, ... along the way did a working rehearsal right there in the tech talk area. Super-interesting to watch and listen to.

A co-worker of mine invited me to come and watch. I'm glad I did. The music was beautiful and I continue to be blown away about how good a classical orchestra can sound in even fairly utilitarian spaces

I feel like we should really visit the Opera in the city some time...

Thursday, October 08, 2015

Last Daylight

Out and about while walking the dog tonight, the last bit of daylight is hanging in the clouds. A few minutes later it was all gone.

Wednesday, October 07, 2015

Sunday, October 04, 2015

Fixing a Hans Grohe Thermostatic Shower Valve

A couple years ago we had a Hans Grohe thermostatic shower valve and trim installed during a bathroom remodel. These valves are excellent at keeping temperature while in shower, even when other users in the house turn on hot or cold water.

Over time, however, the temperature handle started to loose friction and moved by itself, which turned an enjoyable shower experience into an annoyance. In early September I contacted Hans Grohe technical support for advice. After they got the exact part numbers from me (04226000 "thermostatic trim", and 01850181 "rough i-box") they sent out replacement parts no questions asked.

Today I finally installed the replacement parts. First I removed the handle and pulled off the trim. Yes, we have hard water...

Pulling off the trim should be easy, though for a little while I wasn't sure

if I was doing this right. It's just pushed on top of the cartridge, but

sat quite tight in the base trim. Nevertheless, with some care it came

out with no problems.

After turning off the water, I replaced the thermostatic cartridge, and installed the new trim.

Bottom-line: This was a pretty easy maintenance, and I'm very happy that Hans Grohe support was so easy to work with.

Over time, however, the temperature handle started to loose friction and moved by itself, which turned an enjoyable shower experience into an annoyance. In early September I contacted Hans Grohe technical support for advice. After they got the exact part numbers from me (04226000 "thermostatic trim", and 01850181 "rough i-box") they sent out replacement parts no questions asked.

Today I finally installed the replacement parts. First I removed the handle and pulled off the trim. Yes, we have hard water...

|

| The top of the thermostatic cartridge |

|

| Old and new trim pieces. Notice the extra ring in the new trim. |

|

| Old and new cartridges |

|

| New cartridge and trim installed. There's an additional washer to provide more friction for the handle. |

|

| And everything put back together |

Subscribe to:

Posts (Atom)